Last modified: 2023-11-21 21:56:28

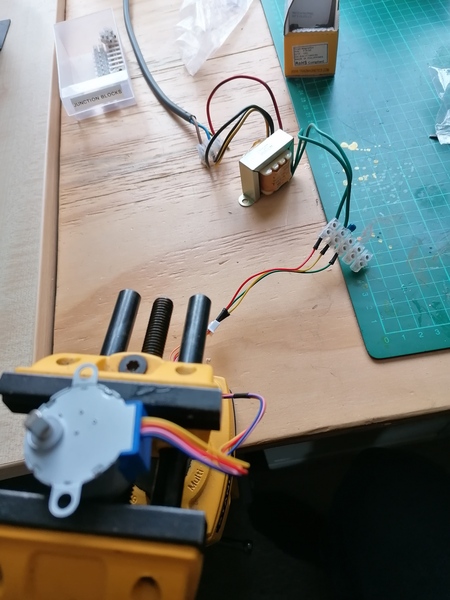

< 2023-11-20 2023-11-22 >First job: wire up a Digi-Key stepper motor, capacitor, and transformer, and check that they work as intended.

Yep! Looks good.

And this is with the 12v motor running on 6.3v. I'm going to leave it running for a bit and see if anything gets warm. Started at about 9.20am.

I also want to time 10 revolutions or something and see if it looks believably like it takes 10.24 seconds/rev. I'm going to risk the DuckDuckGo stopwatch again.

Lol, nowhere near. This is about 4x faster, probably 2.56 secs/rev. Frustrating, I expected the ratio to be the same. I timed 1m37.31s for 38 revolutions = 2.5607 seconds/rev. I think running faster might make it look cooler though, just needs another factor of 4 on the geartrain.

These are the markings on the Digi-Key motors:

(ROHS) STEP MOTOR 28BYJ-48 12VDC 1:16 20230324037

So I'm trying to work out a train that would work for this. A first point of reference is obviously 1:40 8:45 8:50, which is the same as the train on my clock, but with 40 teeth on the Geneva drive. The Geneva drive teeth are quite big, so I'd oibvously like to reduce that a bit and shift some of the extra onto the other gears.

So we could look at 1:30 6:45 8:50.

I wrote a perl script to solve it (in ~/gear-ratios/find3) and the best it came up with was 1:25 6:45 6:45. So let's

go with that, and update the CAD to suit. I'll copy it to a new project so I still have the old one in case I need it.

Damn, a 5mm shaft won't fit through the middle of a 6-tooth pinion at module 1.5.

I just read in https://wiki.freecad.org/PartDesign_InvoluteGear that:

There is currently no undercut in the generated gear profile. That means gears with a low number of teeth can interfere with the teeth of the mating gear. The lower limit depends on the DataPressure Angle and is around 17 teeth for 20° and 32 for 14.5°. Most practical applications tolerate a missing undercut for gears a little smaller than this theoretical limit though.

So that may explain why I have trouble with getting the gears to mesh properly.

One way to get around the problem with the shaft being too big would be to make 3d-printed "lantern pinions", i.e. put a big ring at the end to hold the teeth together even though they are separated in the middle.

I'll go with that for now, but maybe I will want to make my own tooth profiles, to add some clearance for backlash. I definitely want to do that on the Scotch Yoke clock, but maybe best just to get this one done and out of the way.

Damn, the Geneva wheel interferes with the shaft of the second wheel:

It just doesn't end! Maybe I can allow this, if I slide the Geneva wheel forwards and the second wheel back.

12.05pm: the stepper motor is barely even detectable warm, I'm satisfied that it stays cool enough, switching it off.

The geartrain has only ended up 11mm taller than before, not bad.

Looking good for a first pass:

Looks basically the same, except the Geneva wheel thing is much larger.

To make the clocks:

We've took all the stored (hoarded?) wood out of the corner, and put the large kitchen drawers in the corner, to form a desk combined with the small kitchen drawers. Top to be made out of MDF when it arrives.

I think I want materials storage to the left of the lathe, but there are lots of different types of material to store and I want a sensible solution.

This thread has some ideas: https://www.ukworkshop.co.uk/threads/any-clever-ideas-for-wood-and-sheet-storage.119857/

I've applied the "Everbuild Everflex Roof and Gutter Sealant" in between the slabs on the front of the garage roof:

It was very difficult to apply, has given me arm pump. Hopefully it cures the leak though.

It might be good to get 1 hour per revolution at the drum, so that the minute hand can be mounted straight on the drum, and the hour hand geared off that, and then the train just has to speed it up to run the escapement.

If the pendulum beats seconds, then I need 1:1800 speed increase from the train, for example 8:64 8:120 8:120.

A 120-tooth gear at module 2.5 is 30cm across, which in principle is fine, but it means it won't fit on the A4 sheets of plywood I was planning to use, but whatever, let's just proceed for now.

We could also have 6:64 6:75 6:81, which then would make gears that fit on A4 at module 2.5. What's the smallest module we can cut with a 2mm tool? Looks like module 2 would just about be OK:

At module 2, what's the largest gear we can fit within 210mm across? 102 teeth would just about fit.

So if we're allowed up to 102 teeth on the wheels, how big can we get the pinions? What about 8:96 8:96 8:100? Don't know why I didn't notice this solution earlier, it seems strictly better than 8:64 8:120 8:120.

And then the question is: do we prefer 8-tooth pinions at module 2.0, or 6-tooth pinions at module 2.5? I think 8 teeth at module 2.0.

So we'll have a drum with a 96-tooth gear on it, with diameter about 16mm (so that we get 30 turns out of 1.5 metres drop, so 1.5 metres will run it for 30 hours).

On the front of this there will be a gear with a friction drive of some sort, connected to the minute hand, and the 1:3 1:4 arrangement for the hour hand. The face obviously concentric with the drum.

And the drum's 96-tooth gear drives an 8-tooth pinion with another 96-tooth gear, which drives an 8-tooth pinion with a 100-tooth gear, which drives an 8-tooth pinion on the pin disc, which drives the Scotch Yoke in the pendulum.

Most of the pivots will be steel shafts running in brass bushes pressed into holes in the plywood.

If the clock works well (big if) it might be nice to be able to extend it so that the drum moves somewhere else with a factor of 8 or so, so that it only needs winding once a week.

Still to decide: