Last modified: 2023-10-28 09:29:44

< 2023-10-26 2023-10-29 >First job: chamfer the wheels, because they don't look like they'll be changing now. Actually I can't be bothered, skip that.

So on to making hands and face. And the big question is does the hour wheel need an external bearing to support it, or can it just have the internal one that locates it on the shaft? Well one bearing isn't enough to fully constrain it. Maybe we make it stick out a bit further and put two in it? It needs to stick out further anyway so that the hands can clear the face.

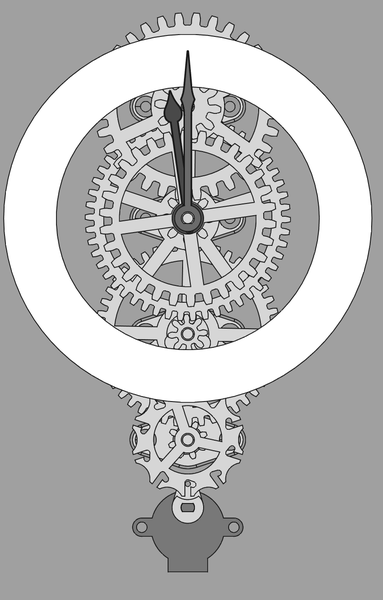

Something like this?

Note that the hands there are aligned in an impossible position - I need to check that it is actually possible for the hands to be aligned correctly. Meh, it's close enough, the counter-wheel is only 1 degree off, which means the minute hand will be a quarter of a degree off. It travels 6 degrees per minute, so a quarter of a degree is about 2.5 seconds.

However it does need the counter-wheel to be aligned with the third wheel and hour-wheel correctly, which may be some trouble to physically assemble. At least it only needs doing once.

I think the transformer should be hidden in the back of the case, and covered with clear plastic or something to stop the mains from getting touched.

And here's a start on the case:

Dial feet:

To be held to side of case with woodscrews, and to dial with countersunk M3 screws into threaded inserts.

So I think I'm actually finished in CAD? Which is very exciting. (So much for designing and making it in one day). I don't have CAD for a face design, heatsink, or electrical housing but they can be improvised after it is proven to work. So next step is making the parts.

First print job, 2h46:

Second print job, 1h27:

So then I need to manually cut the wood for the base and the upright, manually make the shafts, CNC the pockets in the upright, assemble it all, check it works, and then work on making a dial.

CAM for the upright:

Shaft dimensions:

The sizes required for the wooden pieces are:

Maybe it was an error to put the hands in the first print job, as I want them in a different colour. And besides, I put the minute hand upside down so it is mostly trying to print in thin air. Not yet clear whether I will print the hands in a different colour or print them in white and paint them.

< 2023-10-26 2023-10-29 >