Last modified: 2023-09-23 20:16:08

< 2023-09-22 2023-09-24 >Concepts to explore:

This is almost the same tooth geometry as before, except with a 1.6mm radius at the root of the locking face, and a 10mm radius at the root of the unused face:

In lever-escapement-prototype3.

That looks much more like a normal one. Those radii don't really change the geometry of the tooth, they just make it stronger and prettier (and prevent "wedging" in the root of the locking face).

Update: it doesn't work. Need to work out what went wrong.

I think this could have been figured out in CAD. Here both pallets are hitting the escape wheel:

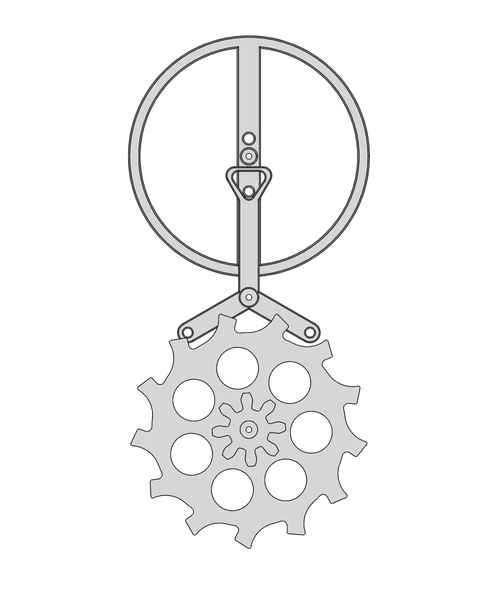

This is the biggest circle that I can fit that allows the pin to pass through the centre position, and also provides sensible clearance from the balance wheel shaft:

The benefit of making it circular is that it can then be drilled instead of requiring tiny milling.

It seems to not work very well, the pin on the balance wheel doesn't push the slot soon enough. I definitely prefer the shape that is narrow at the bottom and wide at the top, although it doesn't need to be as wide as yesterday's one as most of it is unused.

One obvious downside is it increases the weight at the centre of the balance wheel, we'd rather it have all its weight at the perimeter I think.

I actually think it might not be possible to put the slot in the wheel instead of the lever, because after the slot has pushed the lever to one side so that the slot can go past, and then the balance wheel reverses, how can the slot push on the lever?

Is the lever going to be pushed by the "top" of the slot or the "bottom"?

In lever-escapement-prototype4, if I manage it.

This photograph from "Watch and Clock Making and Repairing" by W. J. Gazeley shows that the pallets are not centered equidistant from the pivot:

Instead the locking faces of the pallets are equidistant - I should do the same thing.

In lever-escapement-prototype3.

This time I recorded it with every combination of nuts that I can achieve, from 2 to 14 in steps of 2:

The locking seems to work better now, this is the same escape wheel as the one above where I complained about the issue that I could have figured out in CAD, but with asymmetrical lever to suit it.

The tick rate now drops as the drive torque increases, because I guess the locking works more effectively with more torque?

Increasing torque from 2 to 14 nuts (a factor of 7!), decreases tick rate by about 10%. From 7 (interpolated) to 14 nuts (factor of 2), it only decreases tick rate by about 2.5%.

This is definitely the best one yet. It has the most stable tick rate across varying drive torques, and it also runs over a huge range of different drive torque.

That we're now running slower as more torque is added suggests that we have an excessive amount of recoil relative to the amount of impulse, maybe? So if we made the impulse face slightly longer, would that balance it out so that it's more equal?

Here's a slow-mo video of the latest: https://www.youtube.com/watch?v=hDCr0qx34AQ

Natural frequency of balance wheel

The best-fit line is 2.286 - 0.091 ln(x), R=0.946; is 2.286 Hz the natural frequency of the balance wheel?

I filmed a clip of the balance wheel going back and forth with the lever removed, after pulling it by hand and letting go, and counted frames to work out the tick rate:

It looks like the balance wheel itself is not even isochronous (maybe this is due to making the hairspring out of copper?). "Number of oscillations" is a crude proxy for amplitude, i.e. after 7 oscillations the amplitude has dropped, compared to what it was after only 1 oscillation.

But 2.286 Hz definitely is a possible natural frequency of the balance wheel in the range of amplitudes that it experiences while running. Also note that every frequency I measured with the balance wheel free is higher than the highest frequency I measured with the escapement connected.

I think there might be something to the theory that (for a lever escapement, with locking) the tick rate is f - k log T where f is the natural frequency, T is the drive torque at the escape wheel, and k is some error factor; in an ideal escapement k=0.

If this theory bears out, then working out the value of k for different configurations is a much more legit way of comparing them than the "how much does the tick rate change if I double the drive torque?" question was. So I want to try out some changes to the escape wheel and lever and see if I can find improvements.

It would also be interesting to see whether a steel hairspring gives a more consistent frequency than the copper one.

Update: I think the f - k log T idea is totally bogus, because T above is "number of nuts", which is a totally arbitrary unit. Let's say it truly is f - k log T for the true natural unit of T, then in my case I am looking at T = c n where n is number of nuts and c is a conversion factor. But that works out to f - k (log c + log n) - i.e. the log of my conversion factor gets baked into the fixed constant which I measured as 2.286, so it is just a coincidence that the fixed constant is so close to the natural frequency of the balance wheel.

What actually is the conversion factor from nuts to, say, Newton-metres?

1 nut = 87 grams = 0.87 Newtons

Gear ratio = 0.2

Radius = 9 mm (8 mm barrel + half of 2 mm string) = 0.009 metres

So 0.87 * 0.2 * 0.009 = 1.5e-3, so it doesn't seem like "nuts" works out to a truly natural unit.

I still think the idea that the frequency drops off proportional to the log of the drive torque is believable, and useful, and we should try to minimise the value of k. It's just not quite as neat as f being the balance wheel's natural frequency, because it also bakes in the log of an arbitrary conversion factor.

What is the actual benefit of having the lever pin so close to the centre of the balance wheel? Surely if it were further out it could be in contact with the lever for a shorter duration, and also the escape wheel would have more leverage against the balance wheel?

Maybe the downside is it means the balance wheel loses more energy unlocking the escape wheel?

Not sure, maybe something to consider.

I often find myself filming video clips of things and then stepping through in kdenlive counting frames. Uploading them to YouTube is time-consuming and annoying, and silo's them away in YouTube. I really want something like imagebin but for videos, with these features:

Something to think about.

< 2023-09-22 2023-09-24 >