Last modified: 2023-09-14 15:51:36

< 2023-09-13 2023-09-15 >I finally siliconed the gutter. I also bent up an offcut of cladding to make the last bit of barge boards, and fitted them. So I think the exterior is now 100% done! Great success.

Emma and I tidied up a bit in the alley and conservatory, and tidied up the garage, and took photos of the surplus motorbike parts and I listed them on eBay.

Next up is measuring & ordering wood and plasterboard.

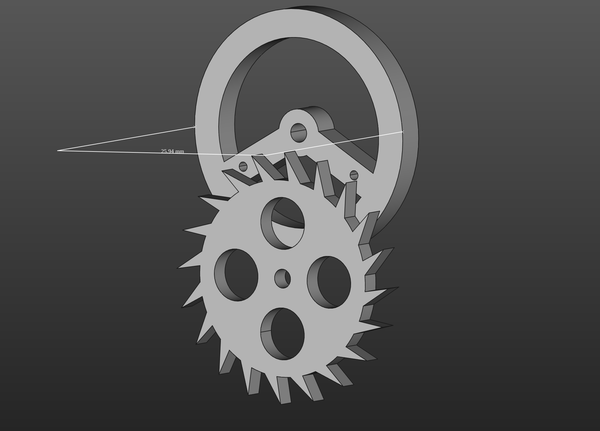

So let's try and proceed on CAD'ing the metal escapement prototype. This is what I have so far:

I think I'll make life easy for myself and skip the separate gear & barrel, I'll just make a frame that can hold these 2 parts, and has some space for me to add the extra bits later. It would be good just to build this up to the point that I can turn the escape wheel with my finger and see it ticking.

Needs a way to attach the hairspring. Let's just say hairspring attachment is a job for a "collet" and proceed without for now. I think I want to get something to show for my efforts, so I'm going to try and make one of these parts using the 1 mm end mill. Wish me luck...

Great success:

I wrote up my experience of micro-machining. The machining took about half an hour, I snapped one 1mm end mill, and used a 5mm collet for the 4mm shank for the second, because the runout with the 4mm collet was too high. Feeds and speeds, and more thoughts, are in the micro-machining doc.

Making the "crossing-out" holes took the longest time. I think a better way to make this part would be to make the disc and bore on the lathe, using the superglue arbor, then transfer to the router, centre on the bore, and use a larger tool to do the crossing-out, and then only switch to the 1mm end mill to cut the tooth profiles.

This evening: do some more CAD.

Tomorrow: make the balance wheel.

< 2023-09-13 2023-09-15 >